Materialguide för borås cotton

Fiber

Polyester

Polyester är den vanligaste fibern i världen idag. Det är en syntetisk fiber tillverkad av icke förnyelsebar källa. I spinningsprocessen ges stora möjligheter på tjocklek samt färg på färdig fiber.

Polyesterfiber ger slutligt material styrka och reducerar krympning. Polyester kan med lätthet tvättas i 60 grader.

Flamsäker FR Polyester & Trevira CS

FR-Polyester och Trevira CS får brandegenskaperna i spinningprocessen. Den icke brännbara polymeren sitter insluten i fibern och kan därmed inte tvättas bort.

Trevira CS är ett patent för FR-Polyester som har gått ut och är nu tillgänglig för alla att använda, men inte under varumärket Trevira CS.

Lin

Lin-fibern tillverkas av lin-stjälkar och dess egenskaper passar väldigt bra till bäddtextil, gardiner och kläder. Det är under tillverkningsprocessen till lin-fibern som garnkvaliteten bestäms.

Bomull

Bomull är en växt som är vanlig att använda i hemtextilier samt kläder på grund av sin mjukhet. Fiberlängden är det som avgör dess egenskaper och kvalitet.

Trycktekniker

Fibervalet på tyget bestämmer vilka olika alternativ till färgpigment och färgteknik som kan användas.

Borås Cotton använder idag två tekniker: digitaltryck och rotationstryck.

Digitaltryck

Digitaltryck kan liknas vid en vanlig dataskrivare. Antingen skriver man ut direkt på tyget alternativt skriver man ut på papper och med hjälp av värme överför tryckpastan till tyget. Fördelarna med denna teknik är att den reducerar vattenanvändning under processen samt att man kan trycka små serier.

Rotationstryck

Rotationstryck görs i stora maskiner med graverade valsar som roterar och trycker på textilen. Rotationstryck har en gräns på antalet färger som kan tryckas då varje vals är en färg. Antalet färger brukar vara max 12 stycken.

Standarder

Flamskydd

Borås Cottons flamskyddade kvaliteter klarar en eller flera standarder för flamskydd. De vanligaste finns förklarade nedan:

DIN 4102 är en tysk standard som mäter reaktionen vid eld. Om gardinen är godkänd att klara kraven för flamskydd så markeras den med B1.

NF P 902-503 är en fransk standard som testas med en elektrisk värmekälla. Resultatet M1 i standarden är det högsta och betyder att materialet inte vill fortsätta brinna.

EN13773 är en Europeisk standard som med resultatet ”Class 1” säger att materialet inte börjar brinna.

BS 5867 är en standard från Storbritannien som är känt som cigarett-testet.

Färghärdighet

Många av Borås Cottons kvaliteter är färgade och tryckta med olika färger och mönster. Kvaliteterna ska behålla samma kvalitet efter användning och tvätt. Färghärdighet kan bli testat med några olika standarder. Om tyget testats enligt standarden ISO 105-B02:2014; Färghärdighet mot artificiellt ljus så har tyget lagts i en kammare med specifik temperatur, luftfuktighet och tid. Resultatet blir jämfört med en standardiserad nivå mellan 1-8 där 8 är det bästa och betyder inga färgförändringar.

Standarden ISO 105:C06:2010; Färghärdighet vid tvätt så tvättas materialet enligt ett standardiserat program med given temperatur. Resultatet anges i nivå 1-5, där 5 är det bästa resultatet med ingen färgförändring.

Ljud – Akustik

Hur mäts ljudabsorption?

Ljudabsorption mäts med hjälp av standard ISO354:2003. En testrapport från ISO 354:2003 ger ett resultat som är jämförbart mellan kvaliteter samt hjälper branschen att kunna räkna ut rätt kvalitet till rätt miljö.

Hur fungerar testet?

Testet utförs i ett specifikt rum skapat för akustiska tester där bakgrundsljudet är lågt. Tyget hängs upp 10 cm från vägg i en del av rummet, både slätt och draperad testas. Testet mäter hur lång tid i sekunder det tar att minska 60dB på frekvenser mellan 100-5000 Hz. Efterklangstiden ligger till grund för resultatet och dess absorptionsklass. Borås Cotton utför sina tester hos Akustikverkstan; www.akustikverkstan.se

Hur används resultatet?

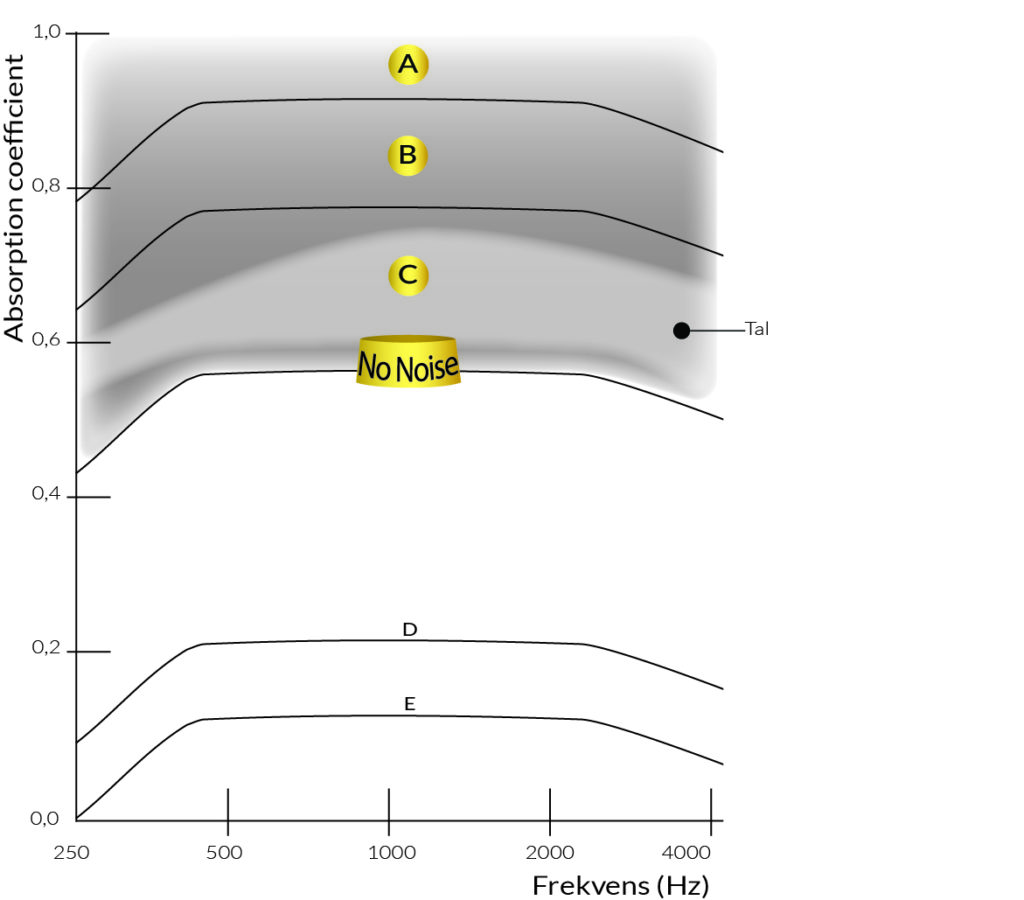

Absorptions-klasserna är indelade från A-E, där A ger bästa absorption.

Rummets utformning kan spela en stor roll i huruvida en lägre klass kan användas och samtidigt uppnå en godkänd miljö. Exempelvis kan ett tyg klasserat med C godkännas i ett A-klassat rum.

Borås Cotton märker upp de tyger i kollektionen som klarar C-nivån och uppåt med en gul ”No Noise” märkn

Kemikaliesäkerhet

Fibervalet på tyget bestämmer vilka olika alternativ till färgpigment och färgteknik som kan användas.

Borås Cotton använder idag två tekniker: digitaltryck och rotationstryck.

Digitaltryck

Digitaltryck kan liknas vid en vanlig dataskrivare. Antingen skriver man ut direkt på tyget alternativt skriver man ut på papper och med hjälp av värme överför tryckpastan till tyget. Fördelarna med denna teknik är att den reducerar vattenanvändning under processen samt att man kan trycka små serier.

Rotationstryck

Rotationstryck görs i stora maskiner med graverade valsar som roterar och trycker på textilen. Rotationstryck har en gräns på antalet färger som kan tryckas då varje vals är en färg. Antalet färger brukar vara max 12 stycken.